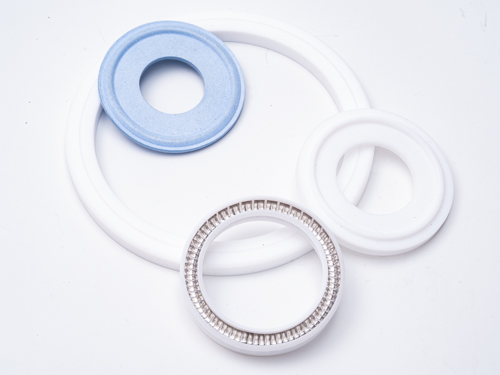

PTFE seals for reliable use

PTFE gaskets from billi are characterised by their high dielectric strength and excellent electrical insulation properties, among other things. Thanks to the wide range of different designs, perfectly suitable PTFE gaskets are available for every application. All items impress with their high processing quality and low thermal conductivity.

Discover the various PTFE gaskets in our online catalogue now and order the right products for your individual application at the click of a mouse.

Order PTFE seals online

The services & advantages of billi seals at a glance

- We produce from 1 piece

- PTFE seals made to measure

- Individual items & customised products

- High quality

- Advice from professionals

- Fast processing

- Large warehouse

- In-house production

- Short delivery times

Order PTFE gaskets from billi cost-effectively and easily

PTFE gaskets are non-flammable and have an extremely long service life. In addition to thread sealing tapes and PTFE cord, we also offer expanded PTFE flat sealing film: The associated items are self-adhesive on one side, which goes hand in hand with convenient fastening. Our comprehensive service is rounded off with personalised advice: we are available to support you with our technical expertise either by phone or email. We will answer your questions about PTFE gaskets and give you specific tips for the ideal product selection. As soon as you have found the optimum PTFE gaskets for your application, you can conveniently finalise your order using our contact form.

As the material is physiologically harmless, PTFE seals are often used in the pharmaceutical and food industries. Another advantage is that PTFE gaskets are very lubricious and therefore do not need to be greased. The materials that are connected to the seals therefore remain clean.

PTFE gaskets are also used in the beverage and chemical industries, as the material has very high chemical resistance in a pH range of 0 - 14. Furthermore, PTFE gaskets have a very high temperature resistance at temperatures from - 200 to + 260 degrees Celsius.

If you decide in favour of a PTFE gasket made of Teflon®, you will benefit from various positive properties. These include

- good electrical insulating properties

- high temperature resistance

- High pressure resistance

- Acid resistance

- High chemical resistance

Thanks to these positive properties, the material is very versatile and can be used very reliably.

PTFE gaskets are very hard-wearing. In addition to almost universal chemical resistance, PTFE gaskets also have very good sliding properties and are extremely temperature-resistant. PTFE gaskets can be used in a temperature range from -200 to + 260 degrees Celsius. Also worth mentioning in the description of PTFE gaskets is their above-average insulating behaviour, even in the event of high temperature fluctuations. This results in very flexible application possibilities.

The service life of the PTFE gasket depends on how the material is processed. PTFE can be processed soft (expanded) or hard (sintered).

A sintered PTFE gasket is extremely durable due to its enormous resistance. Even if the material is under permanent pressure, deformation of the gasket is not to be expected. Expanded PTFE, on the other hand, is characterised by its deformability and adaptation to the sealing space and sealing surface.

For both, high and low temperatures, as well as contact with chemicals, do not affect the material.

We are happy to manufacture your customised gaskets on the basis of special drawings. We can realise a wide variety of special shapes for you. We are happy to advise and support you in the realisation of your special gaskets. We always have traditional flat gasket variants to DIN 2690 standard in stock.

![[Translate to Englisch:] PTFE-Dichtungen"](/header/Spiraldichtungen_billi_seals.jpg)